A Social History of Felt in Canada: Part 7

Industrialization:

Where there is steel, there is bound to be felt…

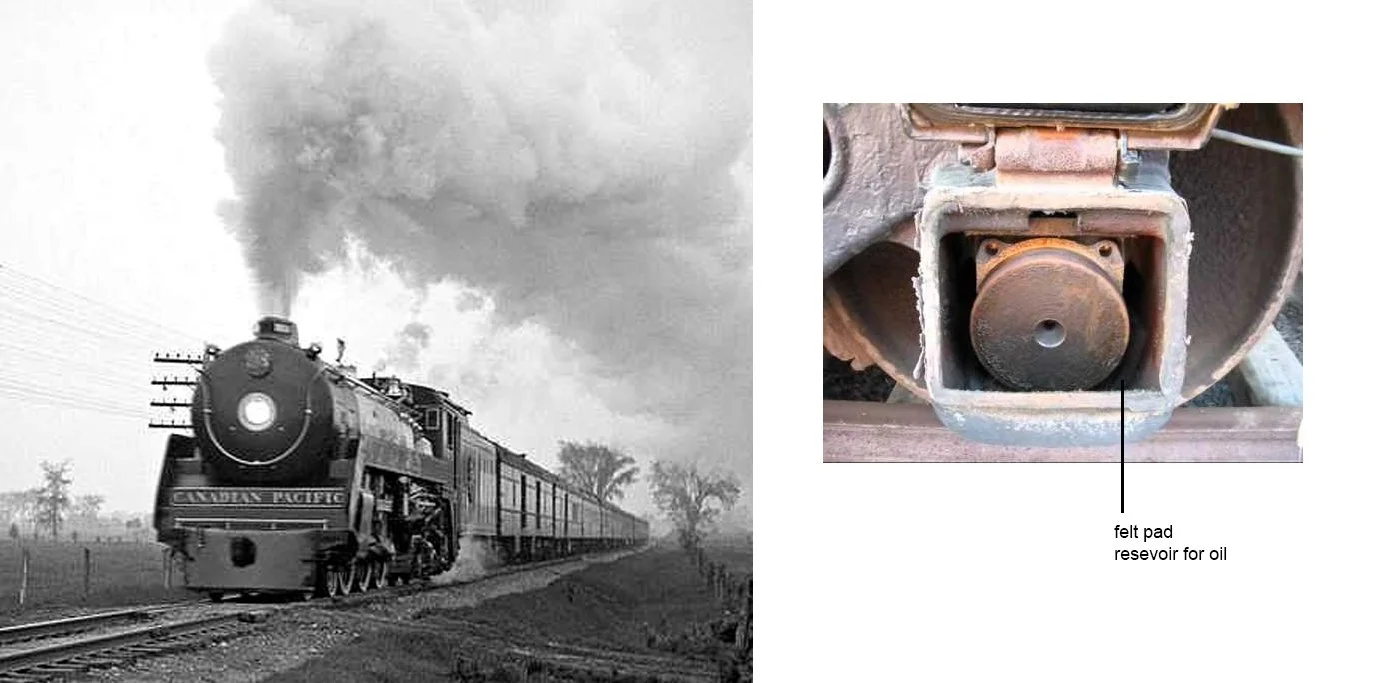

LEFT: Canadian Pacific steam engine, 1930s

RIGHT: journal box

Felt has numerous and wide ranging industrial applications, often playing vital roles in inconspicuous places. The capillarity of felt allows it to act as a reservoir and distributing agent for liquids such as oils for lubrication. Some felts can absorb up to four to five times their own weight. This coupled with resistance to high temperature makes it especially good for high friction areas. During the early days of railroading, felt was there, crossing the country from coast to coast, found in journal box bearings located in the wheels to keeping them rolling smoothly.

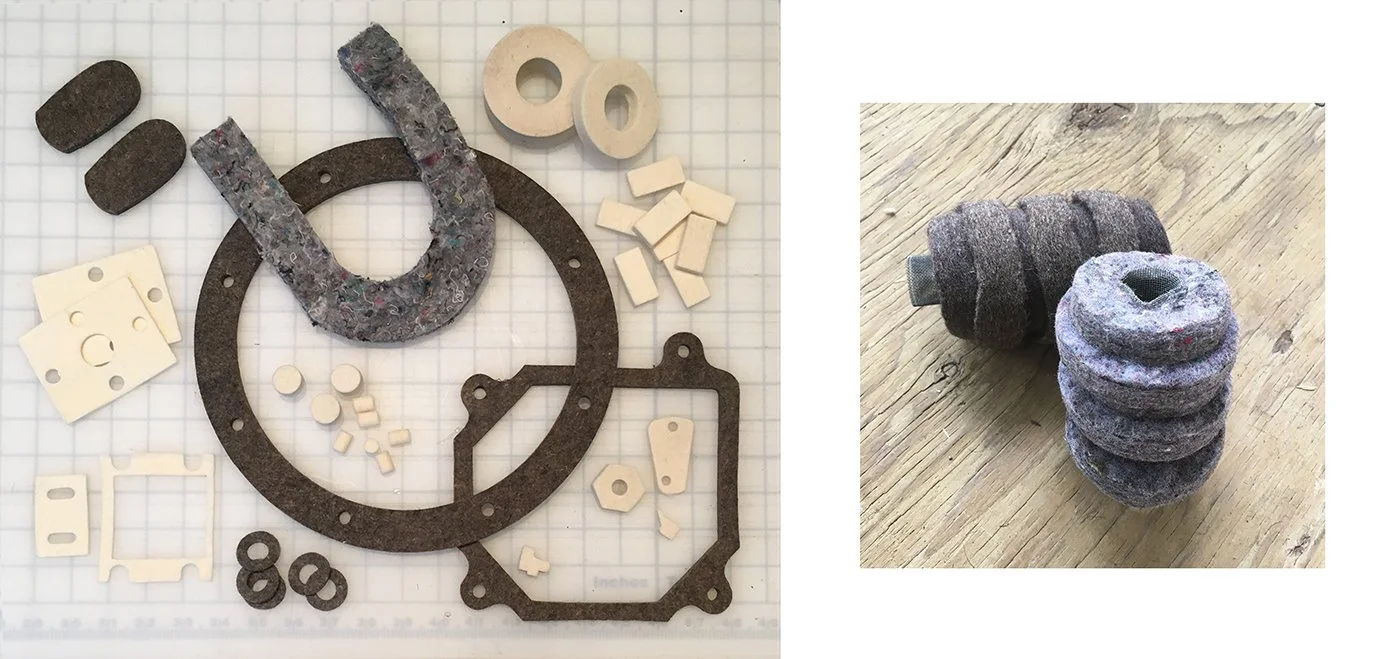

Over 100 different industries have been consumers of felt with over 30,000 applications. These include, but are not exclusive to, shock absorption, vibration isolation, padding, lining, cushioning, packaging, polishing, sound absorption, thermal insulation, lubricating and wicking.

Felt does not fray and so can be die-cut into infinite shapes for machine parts such as gaskets and washers. And miraculously, felt can be both a filter and a seal as it can be processed to a range of densities from soft batting to an impervious firmness comparable to wood without aid of binders. The ability to adjust hardness, elasticity and absorbency in manufacturing has made felt an exceptional engineering material. KW

LEFT: wicks, reservoirs, air filters, fuel filters, polishers, gaskets, washers, seals, vibration dampers, bearing lubricators

RIGHT: appliance filters